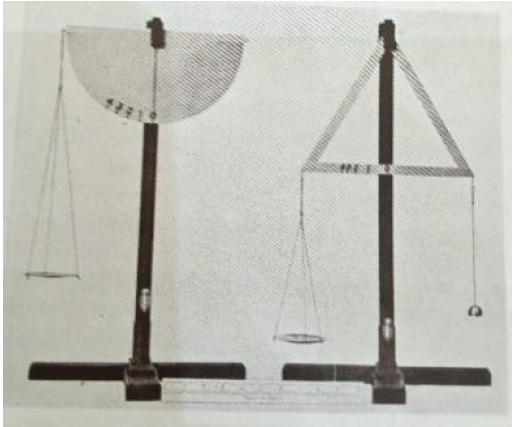

Leonardo da Vinci’s, universal genius of the 15th

century notebooks contain sketches and a description

of two self – indicating weighing mechanisms, one

being semi – circular in form, the other triangular.

The models were constructed by the research department of W.&T. Avery Ltd working from the sketches from Leonardo ‘s notebooks, preserved in Paris.

The models were constructed by the research department of W.&T. Avery Ltd working from the sketches from Leonardo ‘s notebooks, preserved in Paris.

Although Leonardo da Vinci’s sketches of these mechanisms were essentially practical in

conception, no attempt seems to have been made to exploit the invention until 9th century.

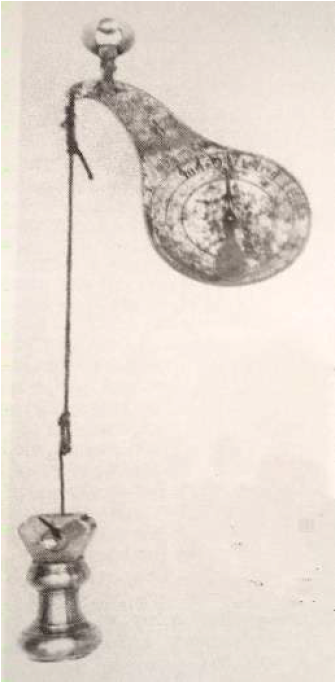

A simple pendulum balance patented in 1863 consisted of a

pendulum made from flat sheet brass and suspended from shackle

as shown in the figure. The load was applied by a cord and ring.

The circular pendulum weight formed a graduated scale at the

centre. When a load was suspended from the instrument, the

pendulum swung outwards to a position of balance and the pointer

indicated the correct weight. These little balances were made for

weighing letters and postal packages.

In chronological order, Richard Salter of

George Salter & Co.Ltd.,West Bromwich is

known to have been made a barrel spring

balance in the year 1770. At first, a

compression spring was used and later spring

balances incorporated tension springs.

Augustus Siebel invented the bow spring balances in 19th century and

subsequently the elliptical spring balances in partnership with

H.Marriott.

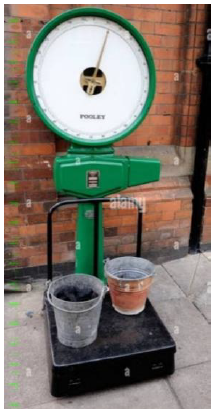

The latter form of resistant and indicator used in platform scale for many years and supplied to Railway companies by Henry Pooley.

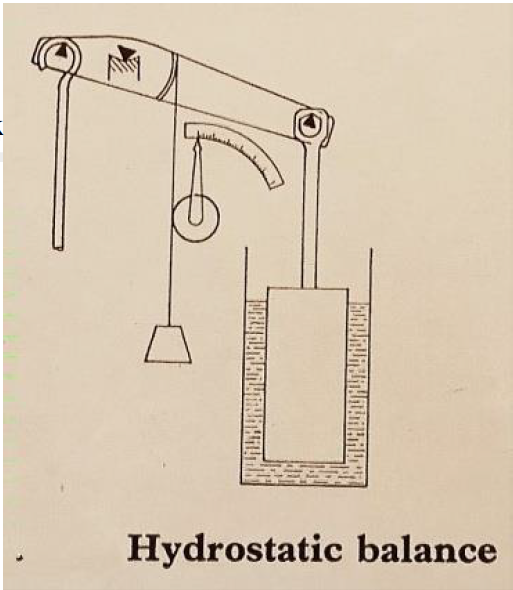

Hydrostatic balances were constructed as early as 1874 by Henry Pooley and some remained in use for many years.

The latter form of resistant and indicator used in platform scale for many years and supplied to Railway companies by Henry Pooley.

Hydrostatic balances were constructed as early as 1874 by Henry Pooley and some remained in use for many years.

The indicator consisted of a beam or lever, one end, which

was connected to a conventional load carrying system of a

platform scale or weighbridge as in the figure. From the

other end, a counter poise was suspended dipping in a tank

of water.

When a load was applied on the platform scale, the

counter poise was raised out of the water, losing part of its

buoyancy until a position of balance was found

automatically. In one version of the scale, an indicator was

driven from motion of the lever by means of a chain and

drum and the weight was thus read on a graduated chart.